Precision OZ Collet for EOC Collet Chuck

$1≥1Piece/Pieces

| Payment Type: | L/C,T/T,Paypal,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Land,Air |

| Port: | Qingdao,Shanghai,Beijing |

$1≥1Piece/Pieces

| Payment Type: | L/C,T/T,Paypal,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Land,Air |

| Port: | Qingdao,Shanghai,Beijing |

Model No.: EOC20,EOC25,EOC32,EOC40

Brand: QFMH

Type: Cutter

Boring Tool Type: Fine Boring Tool

Turning Tools Type: Circular Cutting Tool Surface

Work Type: Cut Off

Cutting Process: Milling Cutter

Structure: Other

Style: Universal Tool

Standards: P

Material: High-speed Steel

Milling Cutter Type: Milling

High Precision DIN6388A EOC8A OZ 25 Collet for EOC COLLET CHUCK , also known as Spring Collet, is mounted on a drill \ milling machine, drilling and milling chuck, its function is to clamp drill cutter or knife. Er flexible collet is currently the most used. Eoc Collet Its stable performance, high accuracy by the majority of manufacturers trust. EOC Collet All products are precision grinding, in line with the German DIN 6499 specifications precision manufacturing.

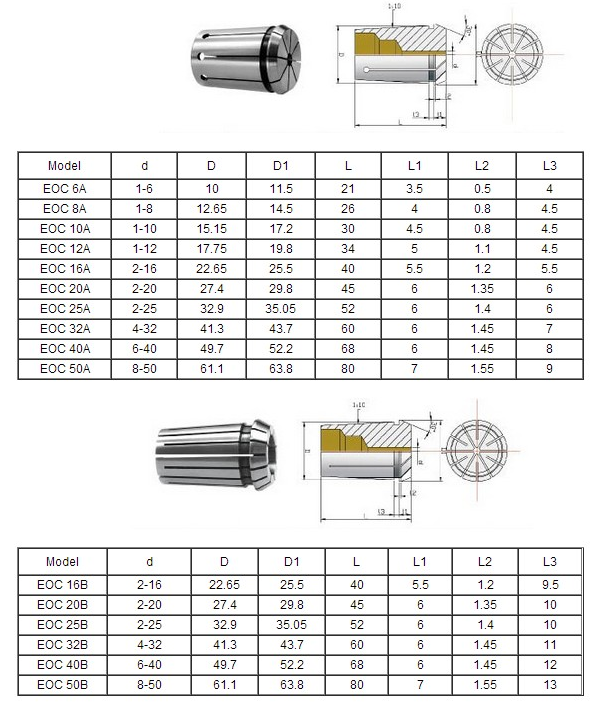

Eoc Spring Collet Specification

● EOC Collet Material: 42CrMo;

● Eoc Milling Collet Hardness: 46-50HRC;

● Precision Collet Grinding within the hole several times, up to Ra0.4, played a mirror effect;

● ,Eoc 25 Collet Cylindrical blank sockets adopt grinding processing technology, more suitable for high-speed processing;

● Cylindrical and end face grinding, up to Ra0.4, play a mirror effect;

● Surface "green" special coating treatment, improve the surface hardness, wear resistance, improve cleanliness, more stable accuracy, the surface is more smooth, rust, better corrosion resistance, feel more comfortable and more beautiful appearance.

● Spring Collet Cryogenic treatment

1, -185 ℃ super-long cryogenic treatment, so that nearly all the retained austenite into martensite;

2. precipitation of nano-carbide particles, increase the hardness and toughness;

3. Reduce the residual stress;

4. Significantly improve wear resistance.

Aging processing

≥ 100h ultra-long set to remove the heat aging residual stress grinding process.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.