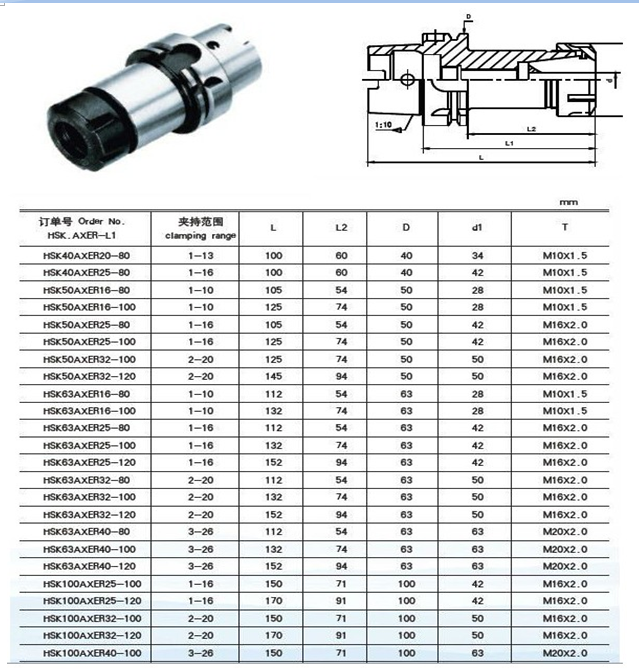

HSK63A tool holder er collet chuck

$1≥1Piece/Pieces

| Payment Type: | L/C,T/T,Paypal,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Land,Air |

| Port: | Qingdao,Shanghai,Beijing |

$1≥1Piece/Pieces

| Payment Type: | L/C,T/T,Paypal,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Land,Air |

| Port: | Qingdao,Shanghai,Beijing |

Model No.: HSK30,HSK40,HSK50

Brand: QFMH

Type: Cutter

Boring Tool Type: Fine Boring Tool

Turning Tools Type: Circular Cutting Tool Surface

Work Type: Cut Off

Cutting Process: Milling Cutter

Structure: Other

Style: Universal Tool

Standards: P

Material: High-speed Steel

Milling Cutter Type: Milling

| Selling Units | : | Piece/Pieces |

| Package Type | : | carton |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.