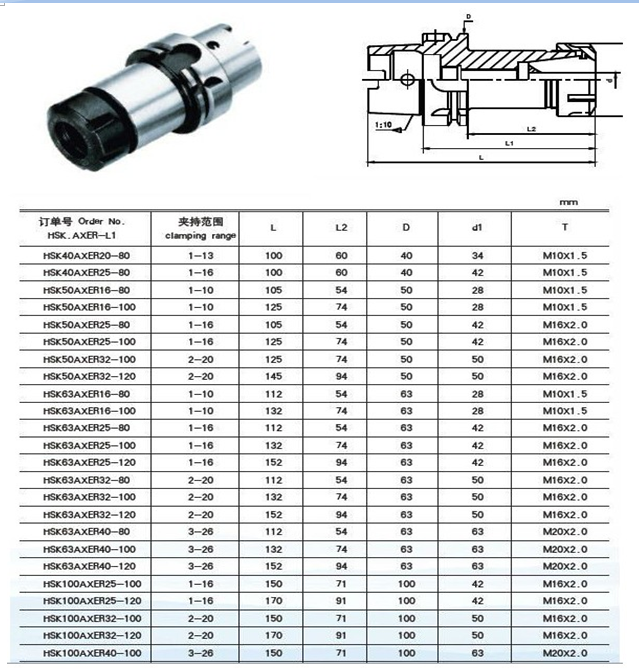

Precision HSK ER Collet CHUCK CNC tool holder

$1≥1Piece/Pieces

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,FCA |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Land,Air |

| Port: | Qingdao,Shanghai,Beijing |

$1≥1Piece/Pieces

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,FCA |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Land,Air |

| Port: | Qingdao,Shanghai,Beijing |

Brand: QFMH

Place Of Origin: China

Status: New

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Turkey, Brazil

Video Factory Inspection: Provided

Mechanical Test Report: Provided

| Selling Units | : | Piece/Pieces |

| Package Type | : | carton |

Precision Hsk Er Collet Chuck Cnc Tool Holder, The unique double-layer positioning clamping mode is designed, the front and rear end stop of the thread is added, the rigidity of the handle is increased by 30%, the anti vibration knife has excellent dust-proof effect.It can be used for drilling, milling, twisting, tapping and other processing, with strong practicability and high cost performance.Please consult separately for customization of non-standard parts.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.