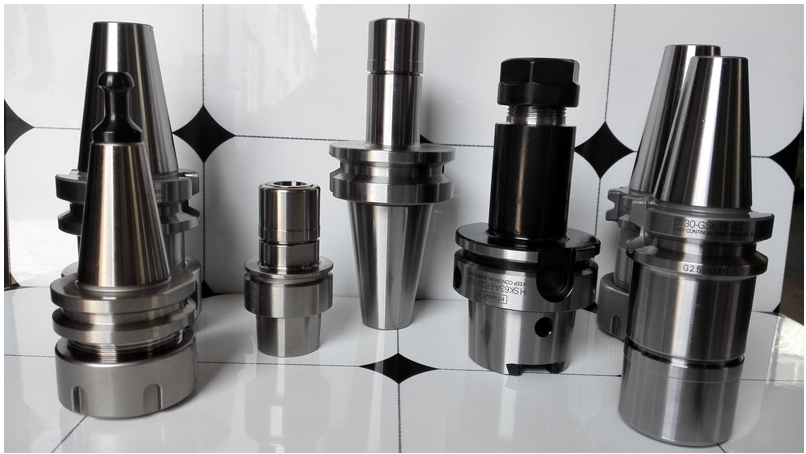

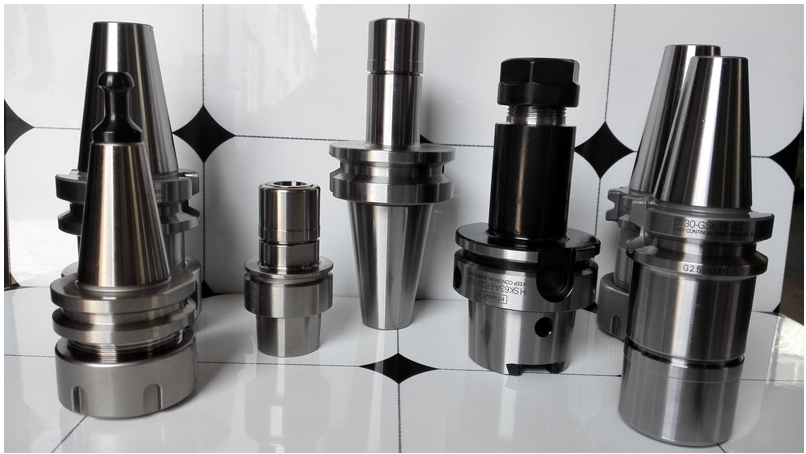

The rigidity, accuracy, durability and dynamic balance performance of the tool are more strictly required in NC machining. Tool selection should pay attention to the structure and process analysis of the workpiece, combined with the processing ability of CNC machine tools, workpiece materials and process content and other factors. The structure of TOOL HOLDER of NC machine tool can be divided into two types: integral mode and modular mode. The working part of the clamping tool of the integral Tool Holder is integrated with the handle used for fixing and positioning on the machine tool. This kind of tool holder has poor adaptability to the transformation of machine tools and parts. In order to adapt to the transformation of parts and machine tools, users must store various specifications of tool holders, so the utilization rate of tool holders is low. Modular cutting tool system is an advanced cutting tool system. Each tool handle can be assembled by a variety of serialized modules. For different parts and machine tools, different assembly schemes can be adopted to obtain a variety of tool shank series, thus improving the adaptability and utilization of tool shank.

The choice of tool holder structure should take into account both advanced technology and reasonable economy. 1. For some simple tools which are used repeatedly for a long time and need not be assembled, it is better to equip with integral tool shank to make the tools rigid and cheap (such as end milling tool shank, spring chuck tool shank and DRILL CHUCK tool shank for processing the outline of parts, etc.). 2. When processing many kinds and small batches of parts whose aperture and depth often change, modular tool holder should be selected to replace a large number of integral boring tool holders and reduce the processing cost. 3. For many CNC machine tools, especially the end of machine tool spindle and tool changing manipulator, modular tool holder should be selected. Because the intermediate module (connecting rod) and the working module (tool loading module) used in each machine tool are universal, the investment of equipment can be greatly reduced and the utilization rate of tools can be improved. In order to improve the processing efficiency, high efficiency cutters and tool holders should be selected as far as possible. For example, the double-edged boring tool holder can be used for rough boring, which can not only improve the processing efficiency, but also help to reduce cutting vibration. The strong spring chuck can not only clamp the straight shank tool, but also clamp the tool with holes through the connecting rod. For typical workpieces with large batches and complex processing, composite cutting tools should be selected as far as possible. Although the price of composite cutting tools and tool holders is relatively expensive, the use of composite cutting tools in machining centers can combine multiple processes into one process and be completed by a single tool, which is conducive to reducing the processing time and the number of tool changes, and significantly improving production efficiency. For some special parts, special design of composite tool holder can also be considered.